Need some help?

We would love to help you with your project.

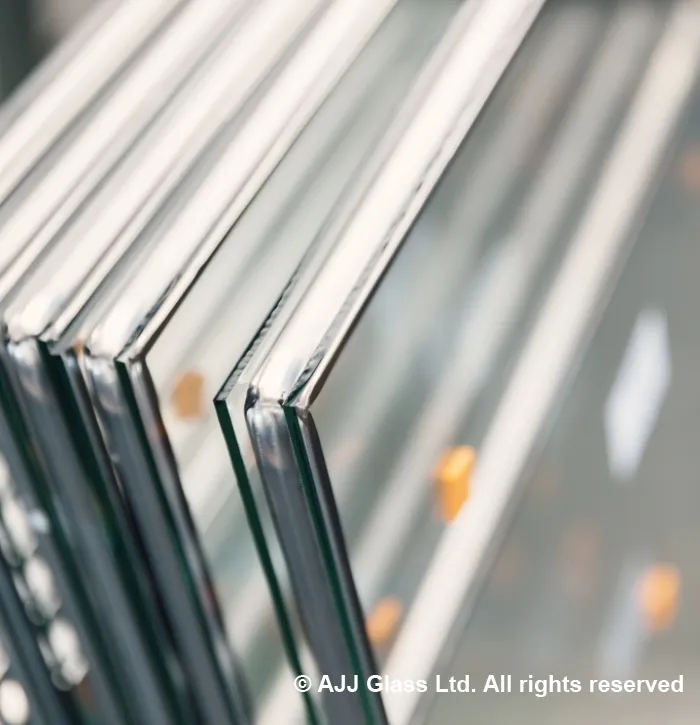

Don’t sacrifice aesthetics for functionality: our range of interlayers and insulation combine decorative qualities with structural and acoustic benefits, such as noise reduction, privacy, natural light, energy efficiency, and UV resistance. Visually captivating laminated glass seamlessly infuses your interior and exterior designs with functional, long-lasting beauty. Using a proprietary process, we create and manually align custom interlayers in our in-house print shop and manufacturing facility. Imagine endless encapsulated possibilities you won’t find anywhere else, from logos to metallics to gradients - even corridor-length, precisely aligned art.

PVB, ionoplast, polyurethane

* Vanceva® is a trademark of Eastman Chemical Company.

BS EN ISO 12543: Glass in building - Laminated glass and laminated safety glass

BS EN 14449: Glass in building - Laminated glass and laminated safety glass - Evaluation of conformity/Product standard

BS EN 12600: Glass in building – Pendulum test – Impact test method and classification for flat glass

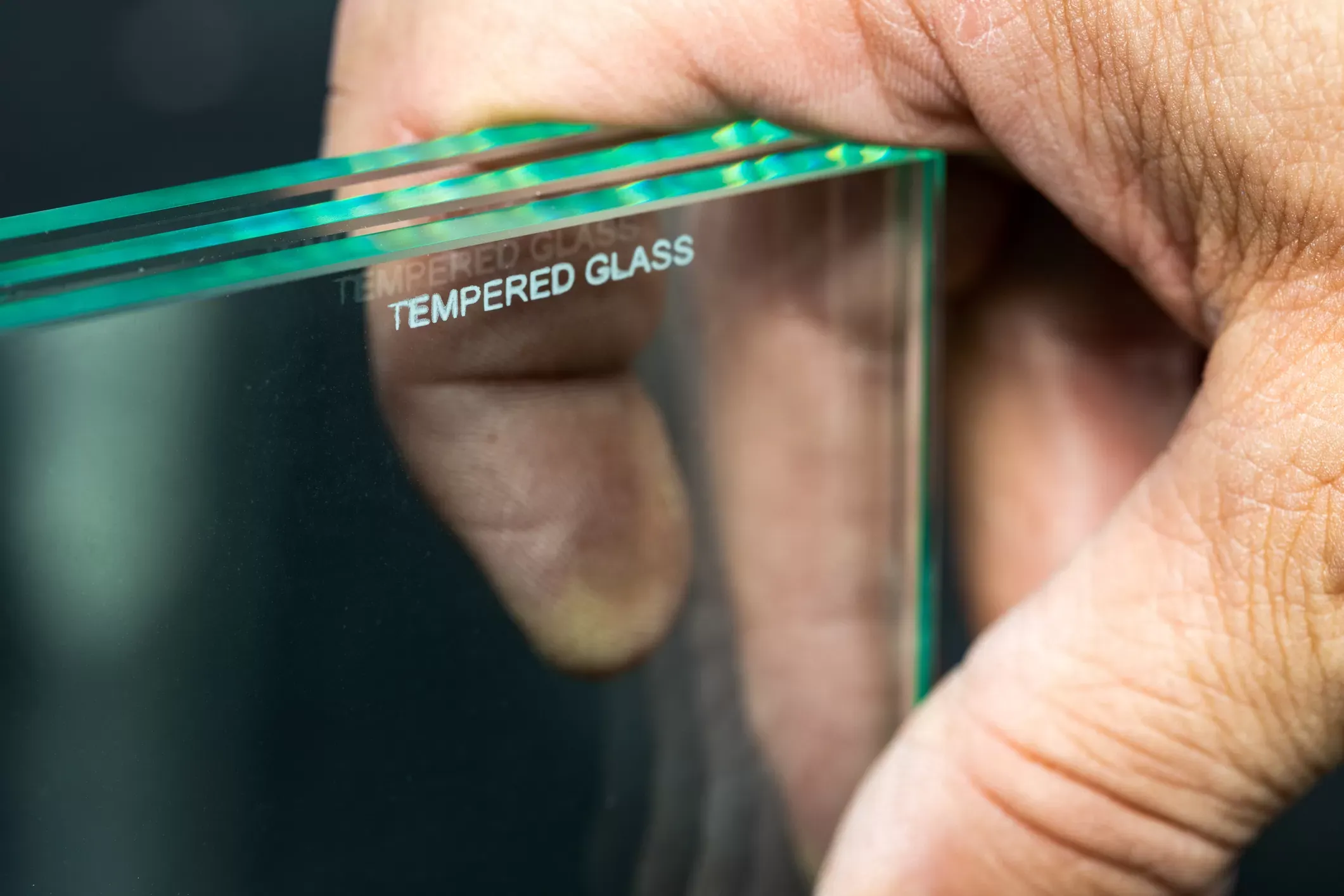

Toughened glass, or tempered glass, or safety glass is one such member of the glass family known to be robust and sturdy.

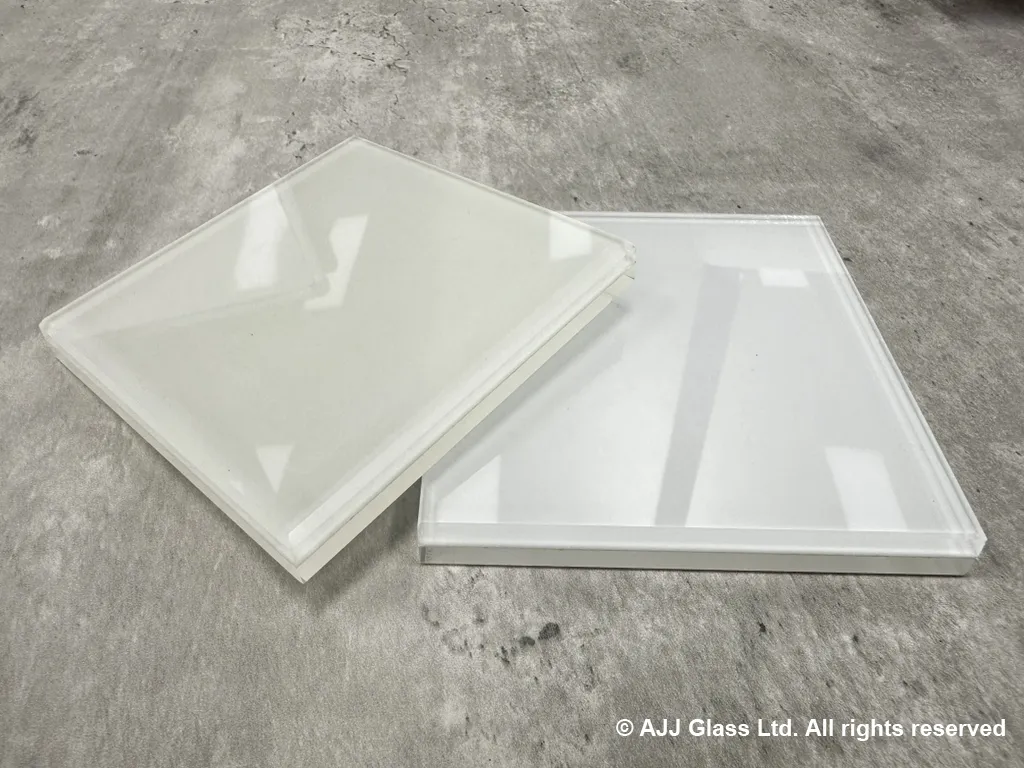

Glass across a full spectrum of vibrant colors, available in a range of translucency levels.

With a stylish frosted appearance, PurColor™ Translucent is durable, reliable, and designed to secure your privacy.