Need some help?

We would love to help you with your project.

Switchable glass, also called smart glass or smart privacy glass, is helping to define the architectural, automotive, interior, and product design industries.

In the simplest definition, switchable glass technologies alter the amount of light transmitted through typically transparent materials, allowing these materials to appear transparent, translucent, or opaque. The technologies behind switchable glass help resolve the conflicting design and functional demands for balancing the benefits of natural light, views, and open floor plans with the need for energy conservation and privacy.

Standard Features

Technical Features

LCD Film consists of:

Test Procedures on Privacy Glass

Suitable for all window and door applications both commercial and residential. Ideal for the following areas:

Clients or their installers should inspect each piece of Switchable Glass before installation. Do not install panels that are incorrectly sized, damaged, scratched, abraded, or deficient in any other way.

Adhere to all Switchable Glass installation guides.

Never install Switchable Glass in a pressure glazing system that does not have a positive stop.

Switchable Glass should never be installed in situations where it may be subjected to any form of loading pressure or mechanical stress, for example, installation into misaligned, damaged, or warped framework or pivot points or to concentrated mechanical loads or actions.

Glazing to exterior and wet interior applications must be wet sealed in a suitable frame and impervious to moisture, with provision for the weeping of condensation that may form in the glazing system.

Electrical connections must be positioned and exit at the head of any installation in wet environment applications and must be completely sealed to be impervious to moisture ingress.

We only recommend the use of Dow Corning AS7096N, or any translucent neutral cure silicone adhesive/sealant.

Ensure all glazing gasket joints are cut and sealed following the relevant manufacturer’s instructions to provide a watertight seal wherever joints are made.

All glass pieces must be supported by two setting blocks. The blocks should have a Shore A Durometer hardness of 85 +/- 5 and be silicone compatible. The preferred location for setting blocks is at quarter points. The electrical connections should not be used to support the glass.

Great care should be taken when installing fixings and fittings to the glass, metal parts should never have direct contact with the surface of the glass or the film, and fittings attached by threaded fixings should be tightened to a maximum torque of 1Nm. To avoid the risk of mechanical threaded fixing becoming loose over time the use of a high-quality thread adhesive in line with the manufacturer’s instructions should be considered.

Unexplained Breakages

This can occur even after all precautions for glass handling, storage, and protection have been observed, this is beyond the control of the manufacturer and as such is not warrantable.

Breakages of this nature can include but are not limited to:

Switchable Glass is an electrical component and should be provided for in the electrical layout including the provision of fused spurs, switches, cable management, and electrical connection boxes. All installations must meet the requirements of local regulations and guidelines and be carried out by a qualified electrician.

Any metal frames that may come into contact with the wiring of the panel MUST be earthed.

Switchable Glass must NEVER be installed in direct contact with a metal frame.

If in doubt consult a qualified electrician before commencing any installation work.

Before installation commences bus bars (the electrical connection to the glass), connection leads and cables should be inspected to ensure the integrity of the insulation.

Wherever possible it is recommended that the operation of Switchable Glass is tested before commencement of installation.

Great care should be taken to ensure that exposed bus bars (the electrical connection to the glass), leads, or cables do not come into contact with the framework and any metal frames must be earthed and are totally sealed to prevent the ingress of moisture or water.

Switchable Glass operates at 110VAC (110 volts alternating current), if the local mains voltage is higher than 110VAC a step-down transformer is required. AJJ Glass supplies a range of thermally protected isolating transformers that are matched to meet the requirements of each installation.

Failure to use either AJJ Glass’s transformers or those of an equivalent specification may result in irreparable damage to the Switchable Glass. (Datasheets can be supplied upon request).

Multiple Smart Glass panels can be connected in parallel to a single transformer up to the maximum M2 rating of each transformer:

50VA – 2 M2

200VA – 10M2

500VA – 25M2

An RCD (Residual Current Device) with an MCB (Miniature Circuit Breaker), or an RCBO (Residual Current Breaker with over-current protection)should be used along with a fused spur at the connection point for Switchable Glass to provide local isolation.

The manual switch or remote control must be wired into the circuit on the mains voltage side of the transformer; failure to observe this requirement may lead to irreparable damage to the Switchable Glass panels.

Before turning on the power to a new installation the electrician must test the resistance reading between the frame and the bus bar feed cables to ensure that the reading resistance is infinite. If this is not the case the short circuit should be found and insulated accordingly.

Create a striking exterior with an unobstructed view.

Gradient Glass is made using direct-to-glass printing techniques that create the gradient effect.

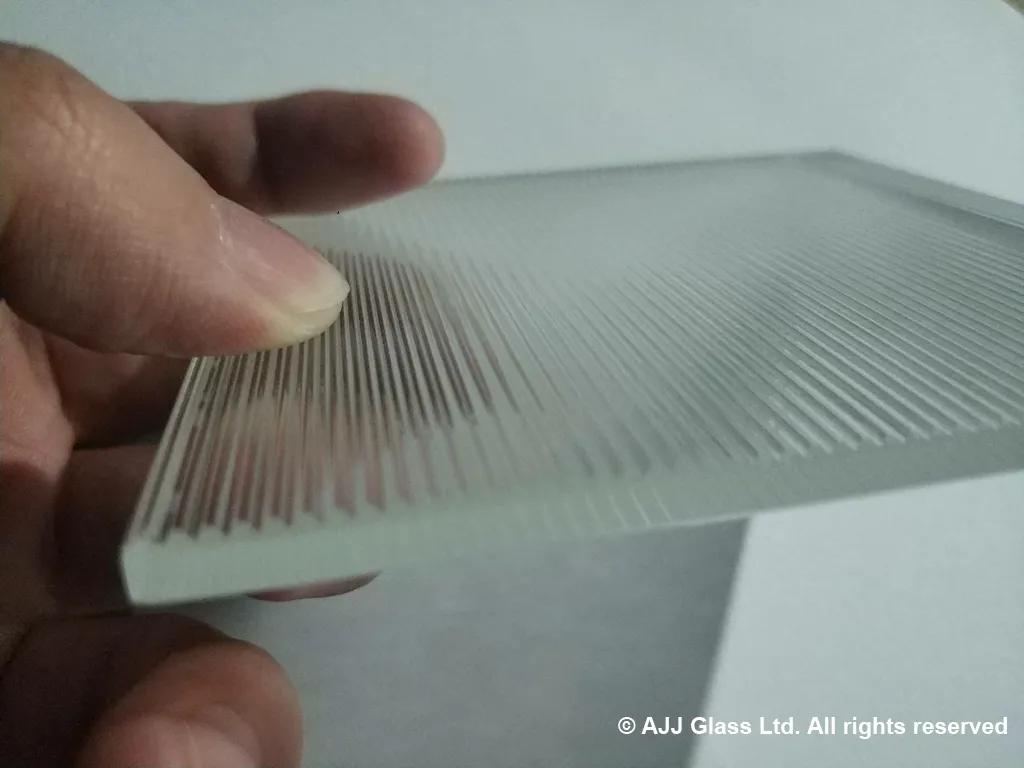

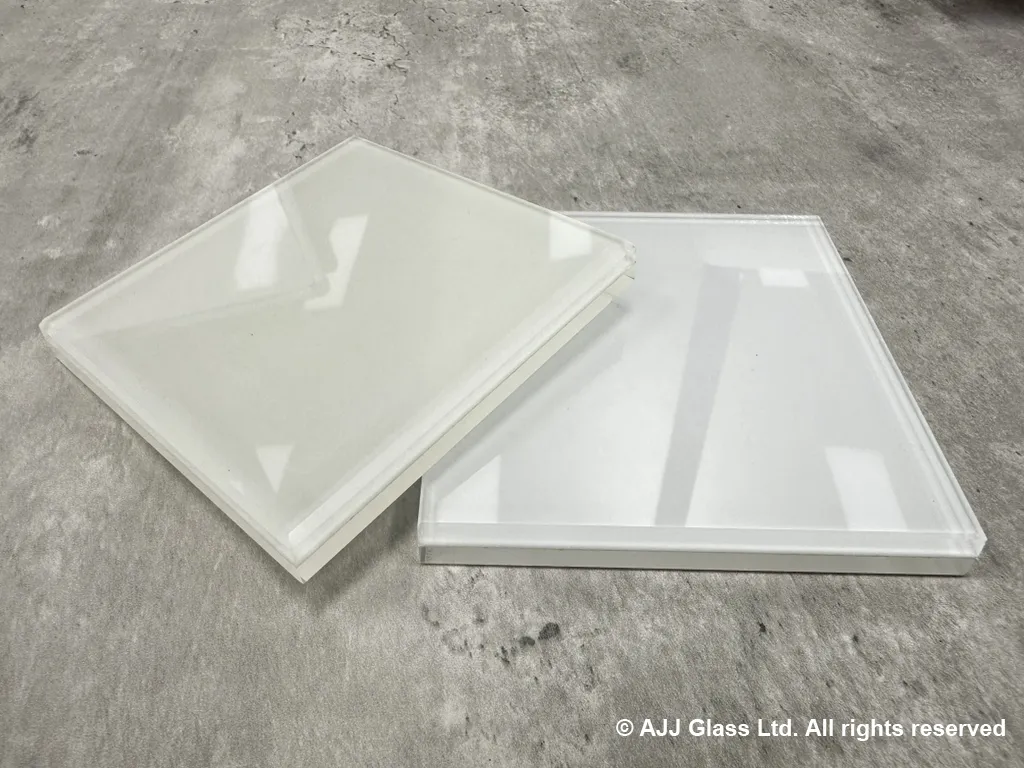

Patterned or textured glass is designed to offer a level of privacy, diffuse incoming light, and provide a design feature in the home or building interior.

Frosted type finish designed for light diffusion providing a level of privacy screening.

With a stylish frosted appearance, PurColor™ Translucent is durable, reliable, and designed to secure your privacy.

Ceramic ink digital printing on glass for a wide range of design possibilities.

Glass across a full spectrum of vibrant colors, available in a range of translucency levels.